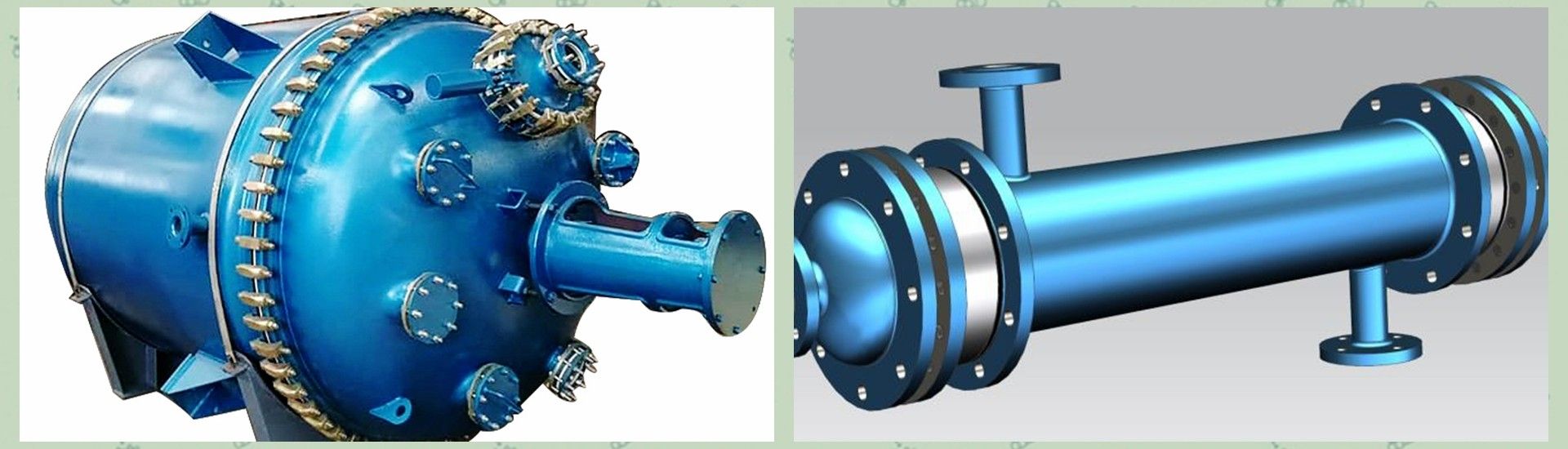

Products >> Stainless steel chemical equipment >> Stainless steel condenser and heat exchanger

10-20m2 Stainless steel tube condenser and heat exchanger

Unique technology of stainless steel tube and shell condenser and heat exchanger:

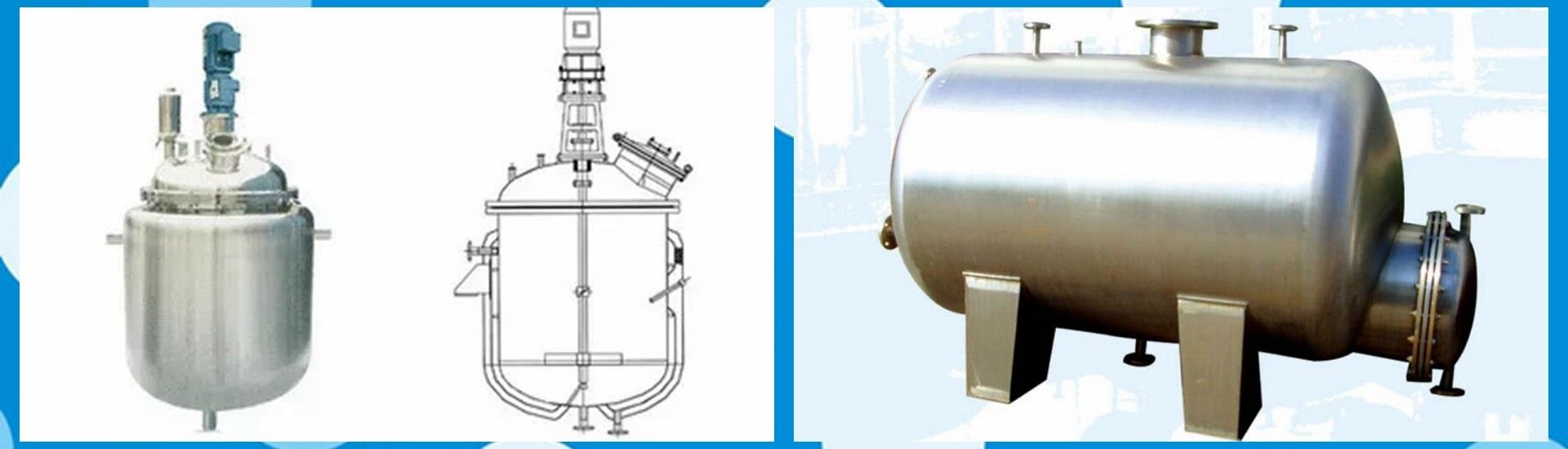

The stainless steel tube heat exchanger can be freely or flexibly formed due to its unique forming process. The characteristic of this process is that during the forming process, the deformation is not caused by the forced flow of metal in the mold, but by the free flow process or the so-called "soft forming" process. Because there is no forced deformation, the forming process will not produce stress concentration, small residual stress, uniform stress distribution, and no intercrystalline stress. Due to its shortcomings, it has strong resistance to stress corrosion.

The stainless steel tubular heat exchanger adopts a new type of high-efficiency heat exchange tube, which has the advantages of strong corrosion resistance, long service life, no pitting corrosion, and low price. Scaling, corrosion and blockage of stainless steel heat exchangers have always been a difficult problem to solve, especially in the case of poor water quality, poor water treatment effects, impurities in gas media or chemical reactions that are prone to scaling. The performance of the light heat exchanger decreases, the working conditions deteriorate, the resistance increases, and the energy consumption increases. The heavy-duty heat exchanger cannot be operated due to clogging, which increases the workload of maintenance, cleaning or updating of the heat exchanger.

Stainless steel tube and tube heat exchanger can withstand high temperature and high pressure difference. Although the wall of the stainless steel heat exchanger tube is very thin (0.5-0.8mm), its pressure-bearing capacity is greatly improved due to its special free forming process and unique arc shape. The one-way breaking pressure of the bellows measured in the laboratory is generally about 20mpa. In actual use, it is safe to control the pressure below 6.4mpa. At the same time, the bellows heat exchanger is made of stainless steel, which can adapt to higher working temperatures, up to 450°C. The bellows is a flexible element with a certain thermal compensation capability. It has good adaptability to large working temperature difference conditions, lower thermal stress on equipment, and has advantages compared with ordinary pipes.

Previous Product:30M2 Stainless steel pressured tube and shell heat exchanger

Next Product:Stainless steel tubular condenser and heat exchanger

Products Category

Contact Us

Name: Ivan

Tel: +86 533 5580757

Mobile/Whatsapp: +86-13054986747

E-mail: [email protected]

WeChat: +86-13054986747

Whatsapp: +86-13054986747

Add: No.7 Zhangdian High-tech zone, Zibo City of Shandong province, China

РУССКИЙ

РУССКИЙ ENGLISH

ENGLISH

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry