Products >> Stainless steel chemical equipment >> High pressure Stainless steel reactor

high pressure hydrogenation reactor and mixing tank vessel

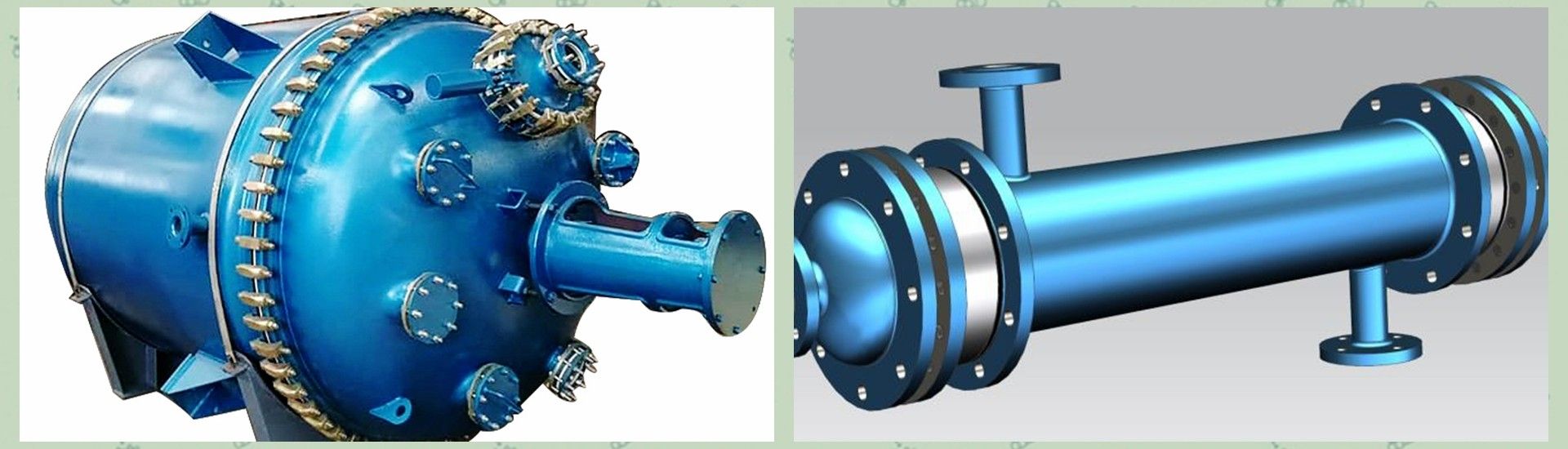

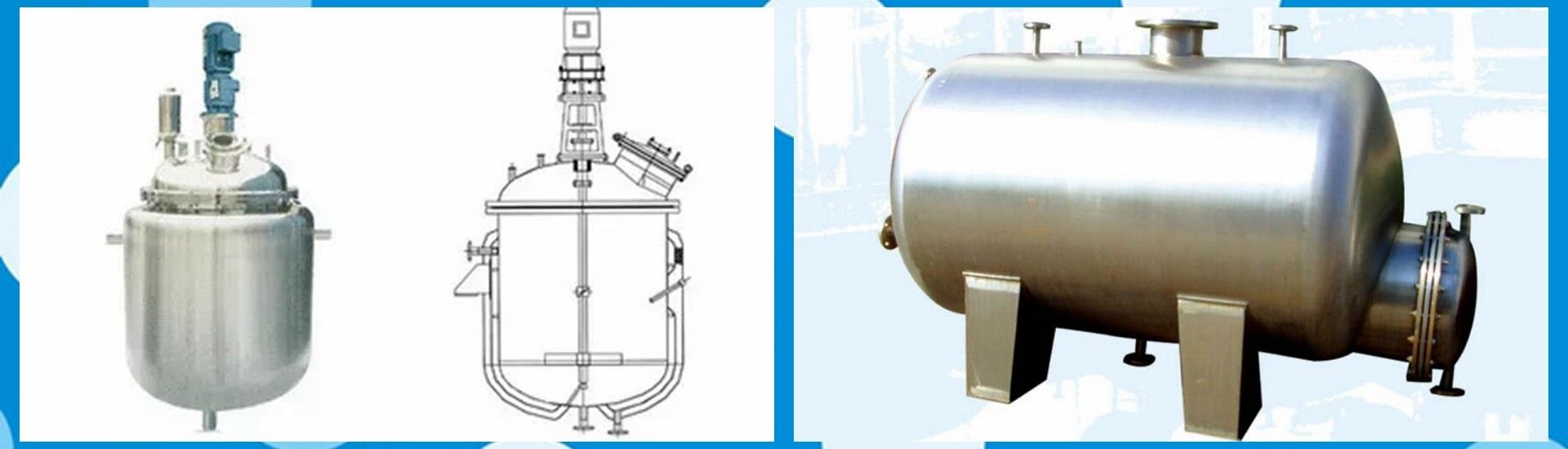

Application scope and structure characteristics of hydrogenation reactor

Hydrogenation reactor is widely used in petroleum, chemical industry, rubber, dye, food, used to complete vulcanization, nitrification, hydrogenation, alkylation, polymerization, condensation and other processes of the pressure vessel, such as reactor, reactor, decomposition pot, polymerization kettle, etc.; The material generally has carbon manganese steel, stainless steel, zirconium, nickel base (Hastelloy, Monel, inkang nickel) alloy and other composite materials; According to the manufacturing structure of the reactor can be divided into open flat cover reactor, open butt welding flange reactor and closed reactor three categories, each structure has his scope of application and advantages and disadvantages.

Hydrogenation reaction kettle consists of kettle body, kettle cover, jacket, stirrer, transmission device, shaft seal device, support and so on. The stirring form generally has the anchor type, the paddle type, the turbine type, the propulsion type or the frame type, the stirring device in the high diameter is relatively large, can use the multi-layer stirring blade, can also be optional according to the user's requirements. And a jacket is set outside the kettle wall, or a replacement hot surface hydrogenation reaction kettle is small in size, the whole machine structure is simple and reliable, economic. Durable. Complete accessories. Standard equipped with the original imported miniature DC motor, pressure hydrogenation reactor is widely used in petroleum, chemical industry, rubber, dye, food, used to complete vulcanization, nitrification, hydrogenation, polymerization, condensation and other processes of pressure vessels, such as reactor, reactor, decomposition pot, polymerization kettle, etc.; The material generally has carbon manganese steel, stainless steel, zirconium, nickel base (Hastelloy, Monel, inkang nickel) alloy and other composite materials; According to the manufacturing structure of the reactor can be divided into open flat cover reactor, open butt welding flange reactor and closed reactor three categories, each structure has his scope of application and advantages and disadvantages. Force meter, explosion-proof device, inlet valve, sampling valve, temperature probe, which can easily realize the micro reflection experiment.

Products Category

Contact Us

Name: Ivan

Tel: +86 533 5580757

Mobile/Whatsapp: +86-13054986747

E-mail: [email protected]

WeChat: +86-13054986747

Whatsapp: +86-13054986747

Add: No.7 Zhangdian High-tech zone, Zibo City of Shandong province, China

РУССКИЙ

РУССКИЙ ENGLISH

ENGLISH

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry