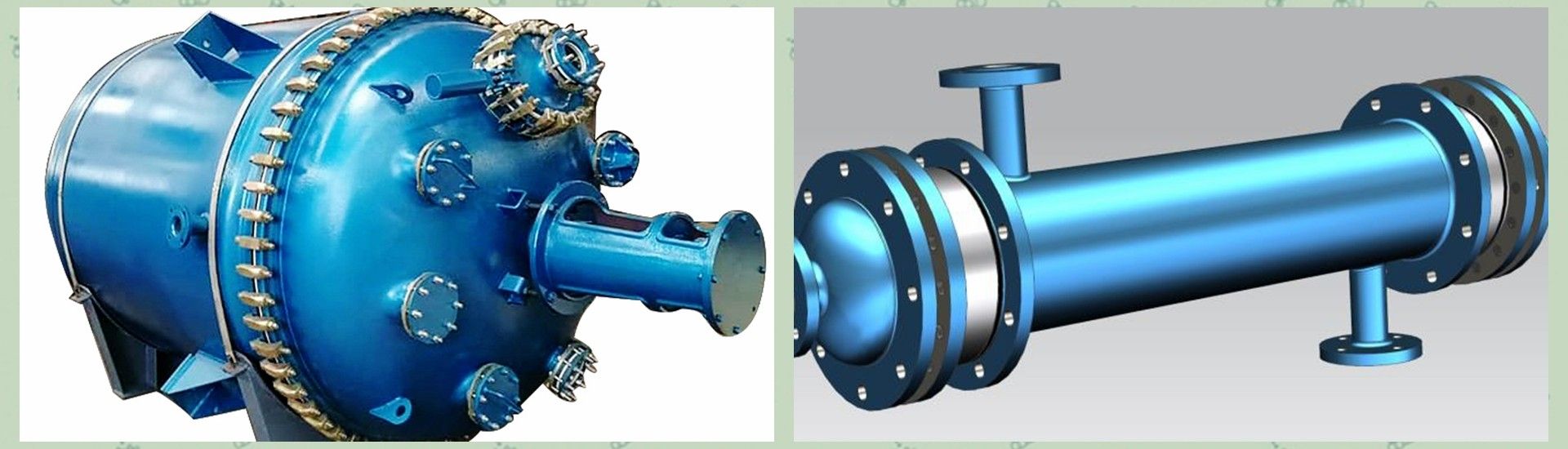

Products >> Stainless steel chemical equipment >> High pressure Stainless steel reactor

100-500liter lab hydrogenation reactor and mixing tank vessel

100L-500L lab hydrogenation reactor / vessel

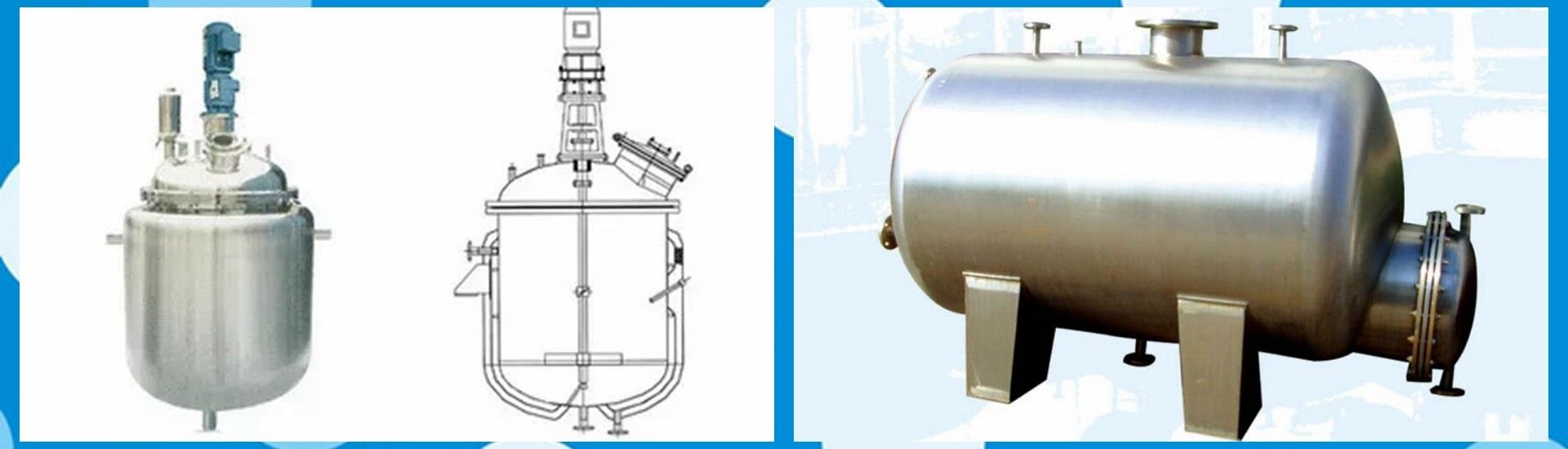

Hydrogenation reactors are widely used in petroleum, chemical, rubber, pesticide, dye, medicine, food and other industries.

The working principle of the hydrogenation reactor is to fully mix the hydrogen, catalyst and materials through high-speed stirring, so as to achieve the effect of rapid reaction.

Materials: alcohols, hydrogen, catalysts (palladium carbon, raney nickel, etc.) and materials (benzene, alkali, alkanes, phenols, etc.)

Volume: 100/200/500/1000L/2000L/3000L/5000L/8000L/10000L/

Temperature: 0~350 degrees

Pressure: -0.1mpa~15mpa

Material: Commonly used materials for contacting materials are S31603, S30408, S32168, Hastelloy, nickel and other non-ferrous metals.

Stirring paddle: The high-pressure hydrogenation reactor is a three-phase mixture of solid, liquid and gas, and whether the hydrogen is mixed uniformly is the key to the reaction. In order to accelerate the mixing of hydrogen, the following 3 methods are generally used:

1. The general structure of the hydrogenation reaction kettle is with a gas distributor at the bottom of the kettle body, and the hydrogen gas is fully mixed with the materials from the bottom of the container through the gas distributor from bottom to top;

The air-efficiency self-priming agitator used by our company works by using high speed to form a vacuum zone around the agitator. The hydrogen on the top of the reactor is sucked into the material through the hollow shaft and the self-priming paddle under the action of the pressure difference. In the case of rotation, it is thrown into the material to form air bubbles to achieve the purpose of full mixing.

Products Category

Contact Us

Name: Ivan

Tel: +86 533 5580757

Mobile/Whatsapp: +86-13054986747

E-mail: [email protected]

WeChat: +86-13054986747

Whatsapp: +86-13054986747

Add: No.7 Zhangdian High-tech zone, Zibo City of Shandong province, China

РУССКИЙ

РУССКИЙ ENGLISH

ENGLISH

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry